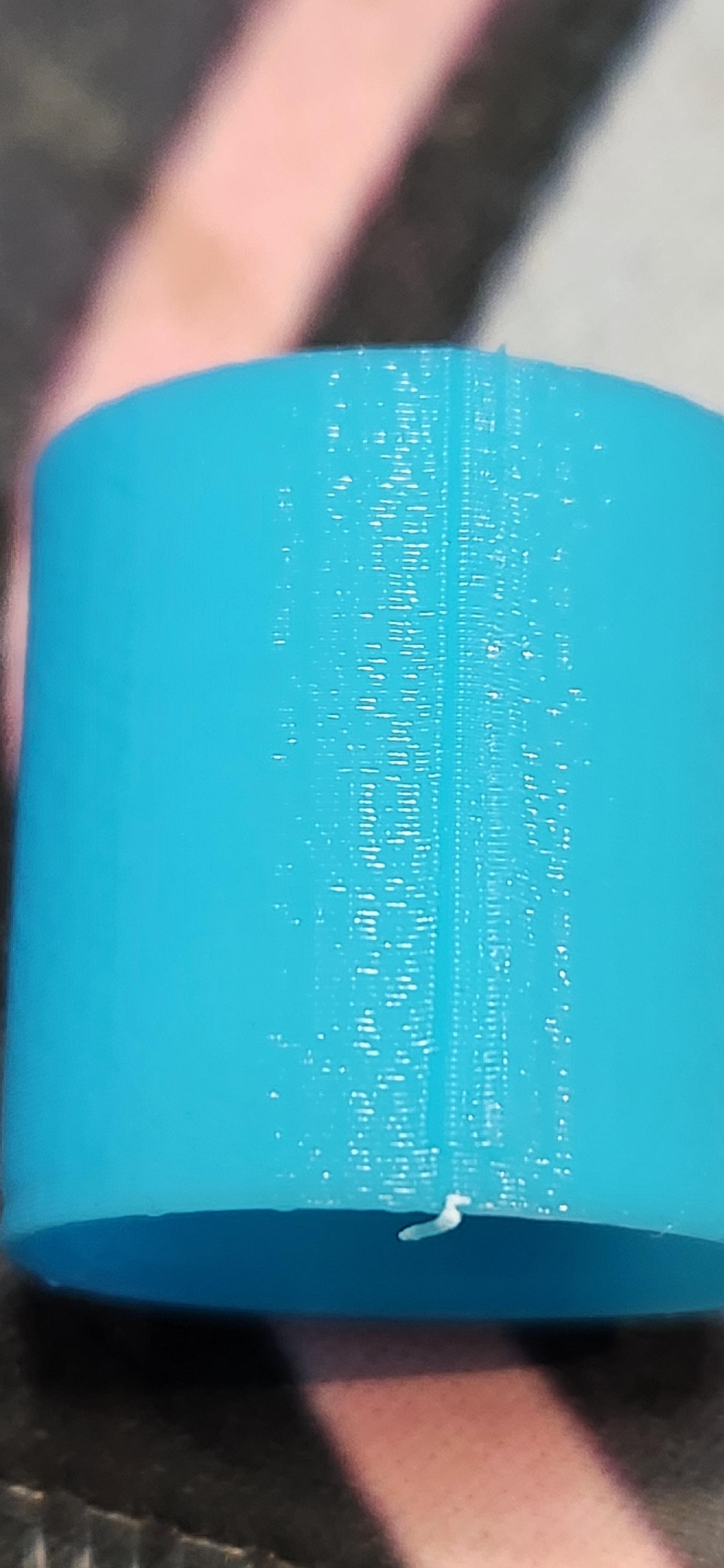

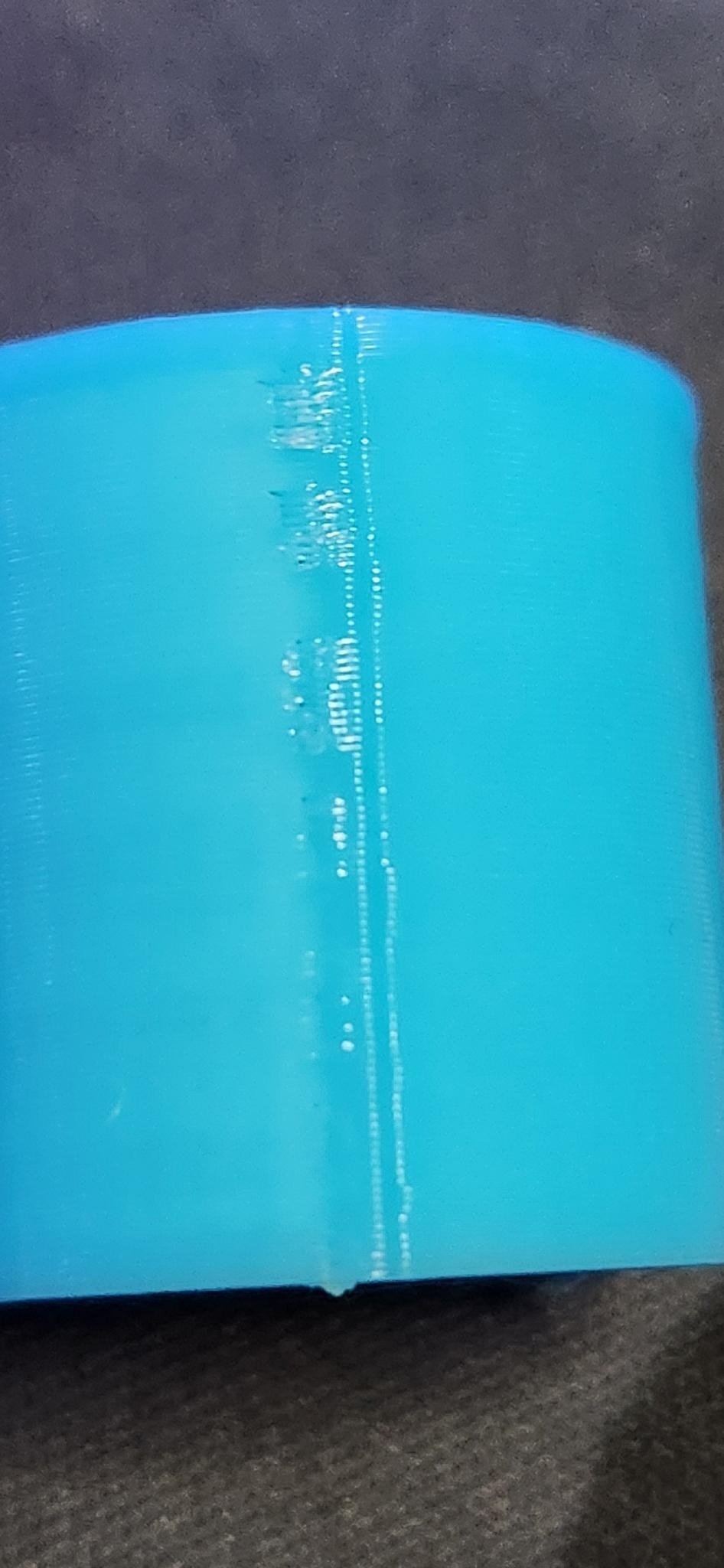

Most probably PA. You should try adjusting it while printing using some g-code console. This way you get immediate feedback. What they often don't tell you is that pressure advance is not something you can calibrate once and forget, it's dependent on material, temperature, nozzle diameter and also a lot on feed rate and extrusion rate.

The need for PA and precise tuning is more pronounced the higher changes in extrusion rate you have eg, you print very fast or with wide or high layers.

Just play around with it a bit and I'm sure that you'll find a better value after some layers.

There are even macros that try to remove the feed rate dependency by effectively replacing every g-code that adjusts feed-rate by a combination of the original g-code pre-ceded by an adjustment of PA. I haven't tried them out yet though.

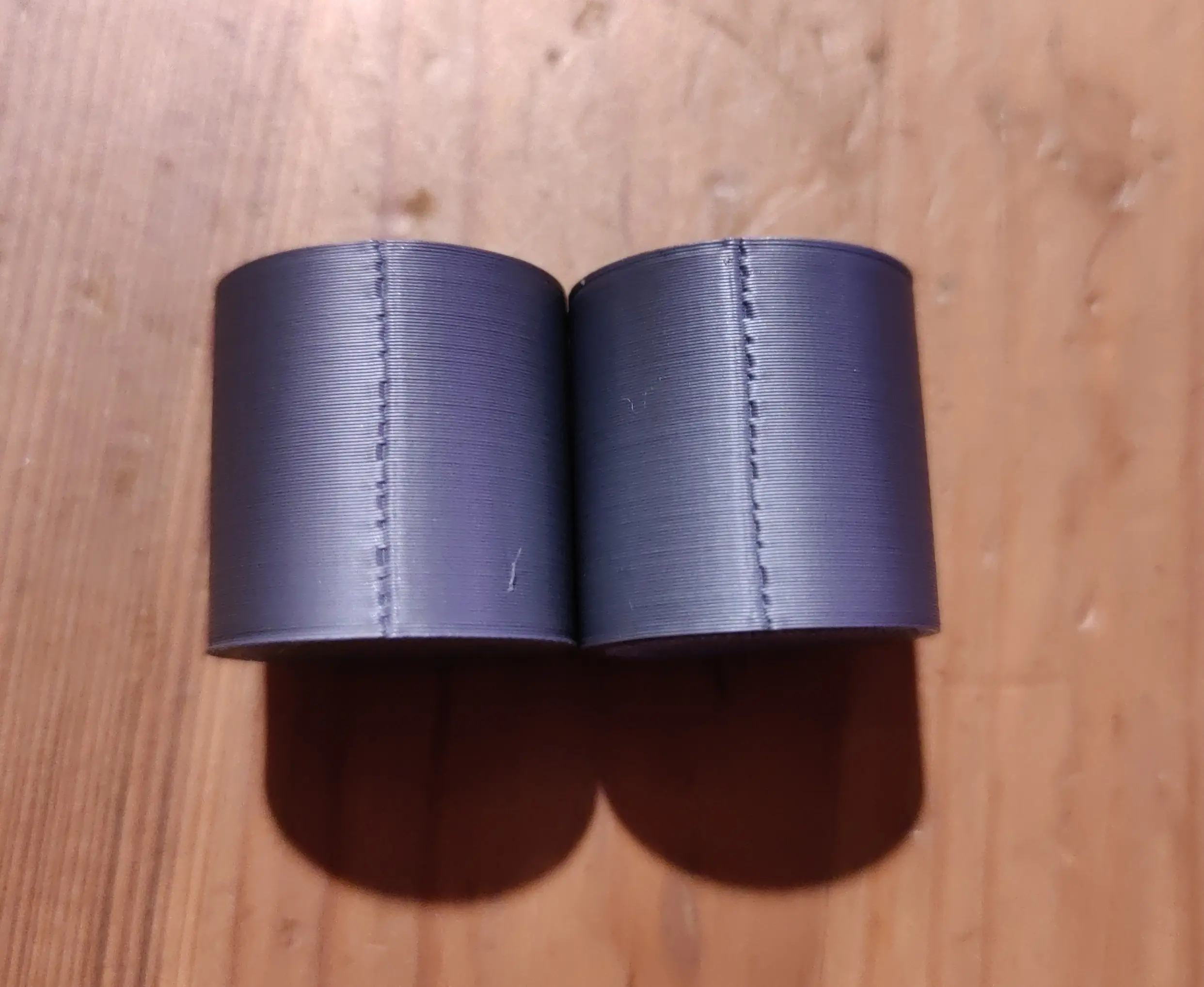

What's weird is the differences of the effect between the layers. Is the every layer the same or is the path different for different layers? Maybe post some images of the inside of the model.