Oh, I am right there with you. I don't want to write tests because they're tedious, so I backfill with the AI at least starting me off on it. It's a lot easier for me to fix something (even if it turns into a complete rewrite) than to start from a blank file.

franzfurdinand

I've used them for unit tests and it still makes some really weird decisions sometimes. Like building an array of json objects that it feeds into one super long test with a bunch of switch conditions. When I saw that one I scratched my head for a little bit.

Same. There's something really cool here and even if I'm not a chess guy, it's still worth it.

Depends on the webapp, traffic, etc. I have an EC2 instance and my own domain that runs me a solid $7 a month. It's just a tiny little web server. If your web app is structured in a way that the client does the processing, your hosting costs can be pretty cheap.

For instance, rather than editing a PDF on a server, if your web app provides all of the tools to edit the PDF in the client's browser, the server doesn't need to be particularly robust. Basically it just needs to hand out those tools to the client.

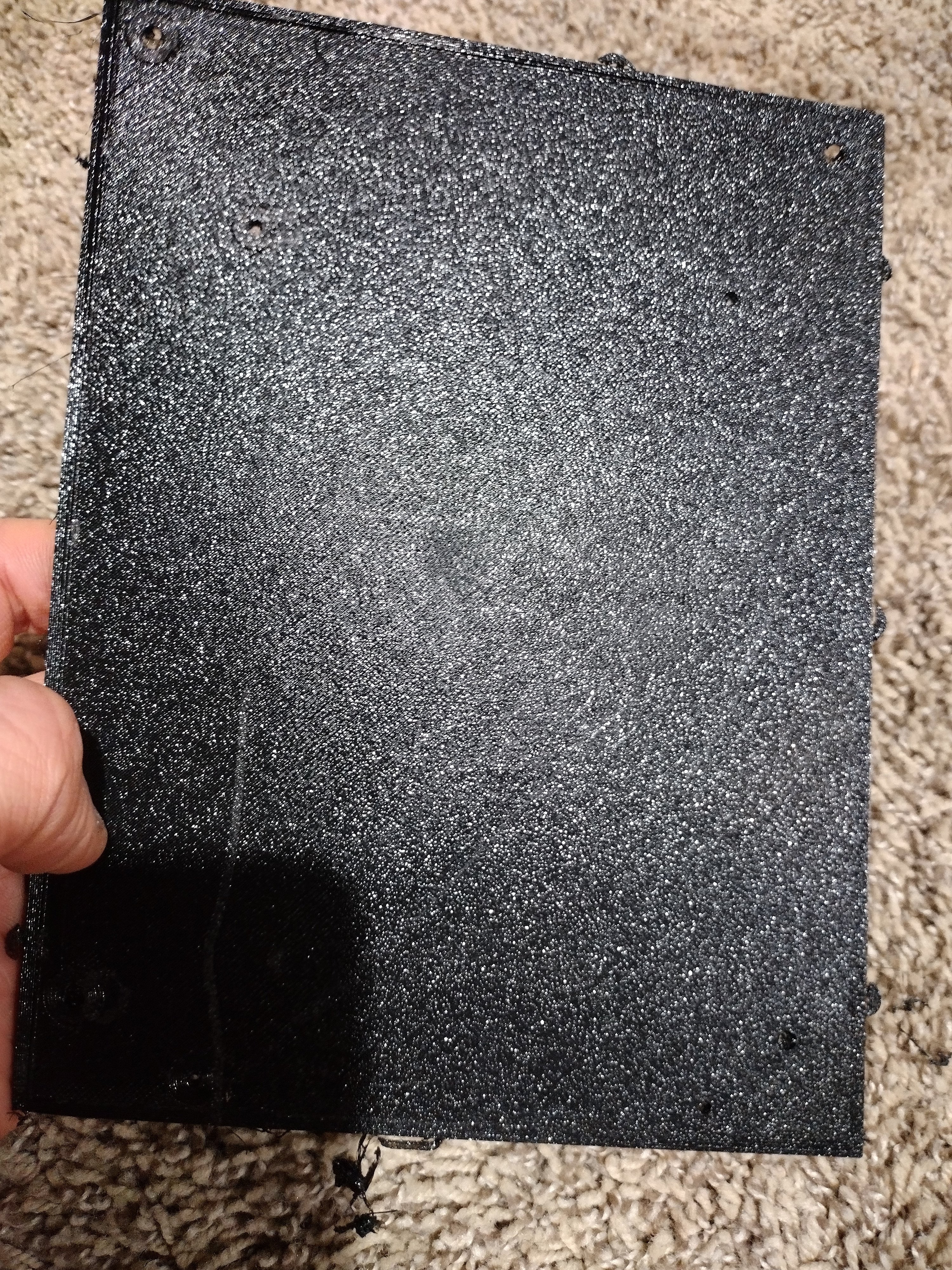

Hoo boy I had it going way too fast. I had it moving at 150mm/s. I very strongly suspect this is about 90% of my problem. Layer quality already seems vastly improved a few layers in at 50mm/s. I very much appreciate the insight!

I haven't run PLA on this printer. This is actually my second one, I modded my first one to the point of unusability. Maybe starting back with PLA is a good idea.

I'll try dropping temps and see what I get. Thank you!

I haven't had issues with curling but the enclosure is pretty new. The room is pretty variable with temps. The windows are old and maybe a little leaky.

Word. I'll give that a go, thank you.

They're sequential, so the values above and below yours are valid SSNs of people born in the same hospital around the same time.

This would make it trivially easy to get access to records you shouldn't

Honestly that could be kinda soothing in a way. A nice little slice of life with low stakes.

One option is 3D printing a mold to fill with silicone sealant. If this is a part that fails regularly, the mold may be worth it. You then have a pretty broad array of food safe sealants you could use and don't have to worry about your 3d printed part harboring bacteria.