There is a lot to unpack here. But my suggestion is "cheap" esp32 devboard. At least where I live, going with older / raw MCU (not a "devboard") will ended up more expensive. I'll give an example. The STM32F103C8T6 "Blue Pill" cost the same as ESP32 DOIT Devkit (around USD 3). BUT the bare MCU of both cost around 1-5 cent more due to the economy of scale. So unless you plan to design a custom board in bulk/size constraint, buying the devkit and making a daughter board can ended up cheaper

bitfucker

I did not know nyarch is a thing. Nice

Why does it sounds like pop manga title

A: Nitya Nil IRL can't hurt you

Nitya Nil IRL:

One of the best manhwa IMHO

Thanks!

What's the name?

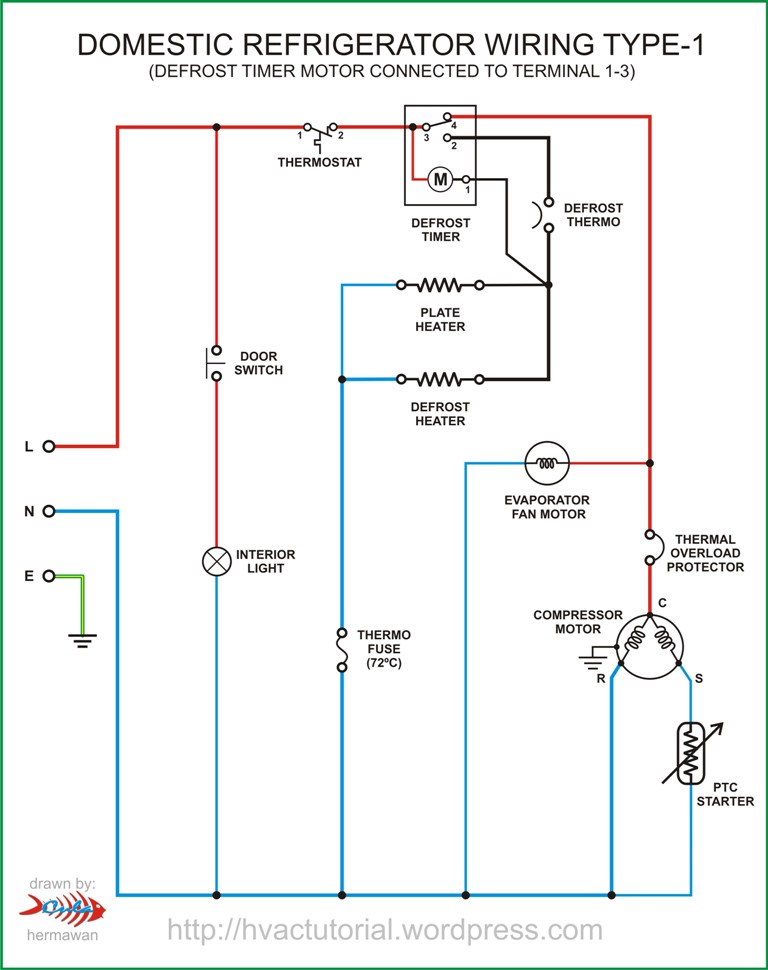

Yeah, that's a broken heater. A broken heater sign is usually high resistance or good ol disconnect. It being in parallel further reinforces that. This is a common schematic for domestic refrigerators.

Ahh, probably a broken heater then. If it is a normally open thermal switch, it should not have that low of a resistance

I've seen the pic. So the plate is not the component? I thought the whole plate was the component. In that case, if it is a small metal plate like any of this, then it most likely is a thermal cutoff.

It's not running the compressor in reverse necessarily. It just used to sense when the temperature of some point has reached some threshold. Remember, a high temperature on the cold side could also be used to trigger the compressor to cool down the fridge.

Oh, it is a big plate. Probably not a thermal cutoff then

If your lithium battery has BMS, it should be fine since a lot of BMS will have a lot of protection including over current. If your raw dog the cell, then as the other said, any voltage and current into the battery should be capped. Ideally, you should monitor each cell as well to prevent an over voltage of any of the cells in the pack. If you want to be safe without monitoring every cell, then just make sure nothing gets back into the battery. Nothing goes in = can't get overcharged by accident from back emf.