Memes

Post memes here.

A meme is an idea, behavior, or style that spreads by means of imitation from person to person within a culture and often carries symbolic meaning representing a particular phenomenon or theme.

An Internet meme or meme, is a cultural item that is spread via the Internet, often through social media platforms. The name is by the concept of memes proposed by Richard Dawkins in 1972. Internet memes can take various forms, such as images, videos, GIFs, and various other viral sensations.

- Wait at least 2 months before reposting

- No explicitly political content (about political figures, political events, elections and so on), !politicalmemes@lemmy.ca can be better place for that

- Use NSFW marking accordingly

Laittakaa meemejä tänne.

- Odota ainakin 2 kuukautta ennen meemin postaamista uudelleen

- Ei selkeän poliittista sisältöä (poliitikoista, poliittisista tapahtumista, vaaleista jne) parempi paikka esim. !politicalmemes@lemmy.ca

- Merkitse K18-sisältö tarpeen mukaan

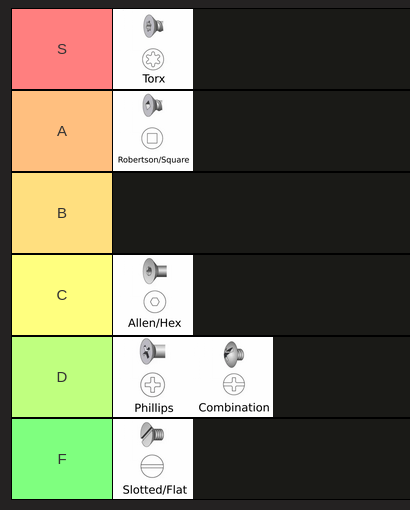

Torx is only good if your screw is non rusting it rounds off too fast with almost any sign of rust.

Torx kinda requires it be made of a decent alloy, it was developed to handle situations where you really really need torque. Handling more force than anything else was the guiding principle of its design.

Hence you find it in places such as bicycle disc brake rotor mounts.

Hex should be B teir. Pozi should be C, it's very common in the UK for low torque applications. But it looks deceptively similar to Phillips.

Hex could even be A tier except...

- 10 million metric sizes

- 10 million imperial sizes

- heads get full of rust or dirt

- note that this makes it even harder to tell which damn size they are

- usually mild steel so they strip, especially when it turns out you're using imperial in metric and vice versa

Too many years of wrenching on old equipment has soured me on all except for the good old fashioned hex bolt (S tier) and Robertson (A tier).

Even slotted beats most of these if the steel is decent, scrape out the rust and whack it with an impact screwdriver. I've turned many torx and hex in particular into slotted over the years.

I could be talked into bumping Hex up to B, I just want it between Phillips and Robertson.

I don't have any experience with Pozi screws in the US, but doing a quick search they look like a solid upgrade over Phillips, so I'm guessing I would agree if I actually used them.

I feel like you didn't give enough credit to slotted and combo (& hex but others have said that). Being able to be removed with a quarter or other coin is incredibly useful in applications where access to screwdrivers isn't a given.

Yeah, combo is where it's at in terms of field serviceability. I pretty much always have a flathead on hand, but very rarely have a torx but set, Allen key, or Robertson close at hand if I'm in the field.

I prefer flat over Philips imo, phillips very easy to strip

I'm a technician and keep my 9 most-used screwdriver bits in its handle and all of these are usually fine for most applications... Except the slotted screw! I literally get annoyed every single time I have to use one, it always slips out and it's significantly slower to screw/unscrew anything. Also, I only want to carry one, but if I use one wide enough to minimize slipping, it's usually too thick to fit in the slot! "Screw" you, flathead screws and the $0.0001 you save with each one...

Here's what I use most often (not necessarily in order):

- big Phillips

- small Phillips

- T25 Torx

- T20 Torx

- T15 Torx

- T10 Torx

- big security hex (hole in the middle)

- small security hex (hole in the middle)

- slot flathead

Robertson Square that high up? This list must have a few loose screws.

I've used them very rarely, but I've never had one strip unlike everything beneath it so I can't complain.

Torx >

This is correct, Torx is easily the best standard. Robertson is an acceptable second.

Posidriv can bugger off too.

When you look at a Robertson, or a JIS or even a Phillips you just use a JIS or Robertson and you’re fine. If it is posidriv, you must use posidriv and you can’t use posidriv with a conventional Robertson/Phillips/JIS. The only way you can tell the difference is by a teeny-tiny little dot on the screwhead or some extra minuscule fins on the driver. If you do t have your glasses, or aren’t aware, you will damage the screw and your driver.

Hex and Torx are OK for certain things where you don’t want an ignorant pleb to gain access. Security Hex and Security Torx are OK where you don’t want an ignorant pleb in denial of their ignorance to gain access.

All those other drivers, Triwing, Pentalobe, variants of Posidriv are just there to push proprietary applications and should not be used by anyone.

Robertson is top tier too

As someone who owned a Jeep in a place where they salt the roads in the winter. Fuck torx.

That being said no other screw head would have been any better, and maybe it was just a cheap torx socket (you could see I had actually twisted the whole head on the tool, before stripping the screw). A hex bolt for that particular application would have been much easier to remove (or snap the head off :p)

Applications exposed to corosion really should use external drive fasteners.

Me out here calling them “plus head” and “minus head” like a neanderthal

we call philips "cross" and flathead "slit"

'cross-head' and 'flat-head' for me

omg I've found my people, you all have strong opinions on screw driver geometry

Might I recommend a book on the matter.

One Good Turn: A Natural History of the Screwdriver and the Screw by Witold Rybczynski

Hey cool my grandfather was named witold. Probably had some strong opinions on screwdrivers too tbh.

I fucking hate Phillips style so much.

Never tried JIS though, Robertson is where it's at.

Do you have a moment to talk about our Lord and Savior Torxus Christ?

Found the Canadian

90% of complaints about any screw head type is some jackass using the wrong driver like a P2 in a P3 head totally mystified as to why their shit stripped.

That's not just user error, though. Phillips also makes it easy to use an undersized driver, and people will grab whatever they have handy. Torx doesn't have that problem, but at the expense of needing a bunch of different drivers for different screws.

How do I identify the screw head size by sight

Pozidriv enters the chat

How does a positraction on a Plymouth work? It just does.

I'm trying to understand what the top half of each diagram is

Taco

Screw this meme

All that lame stuff. Torx it is.

Pozidriv > *

Not only is it self-centering like phillips and JIS (eg the reason they are used in so many line-assembled manufactured goods) but it's has superior contact like a Robertson (square drive) or hex or torx.

Screw you